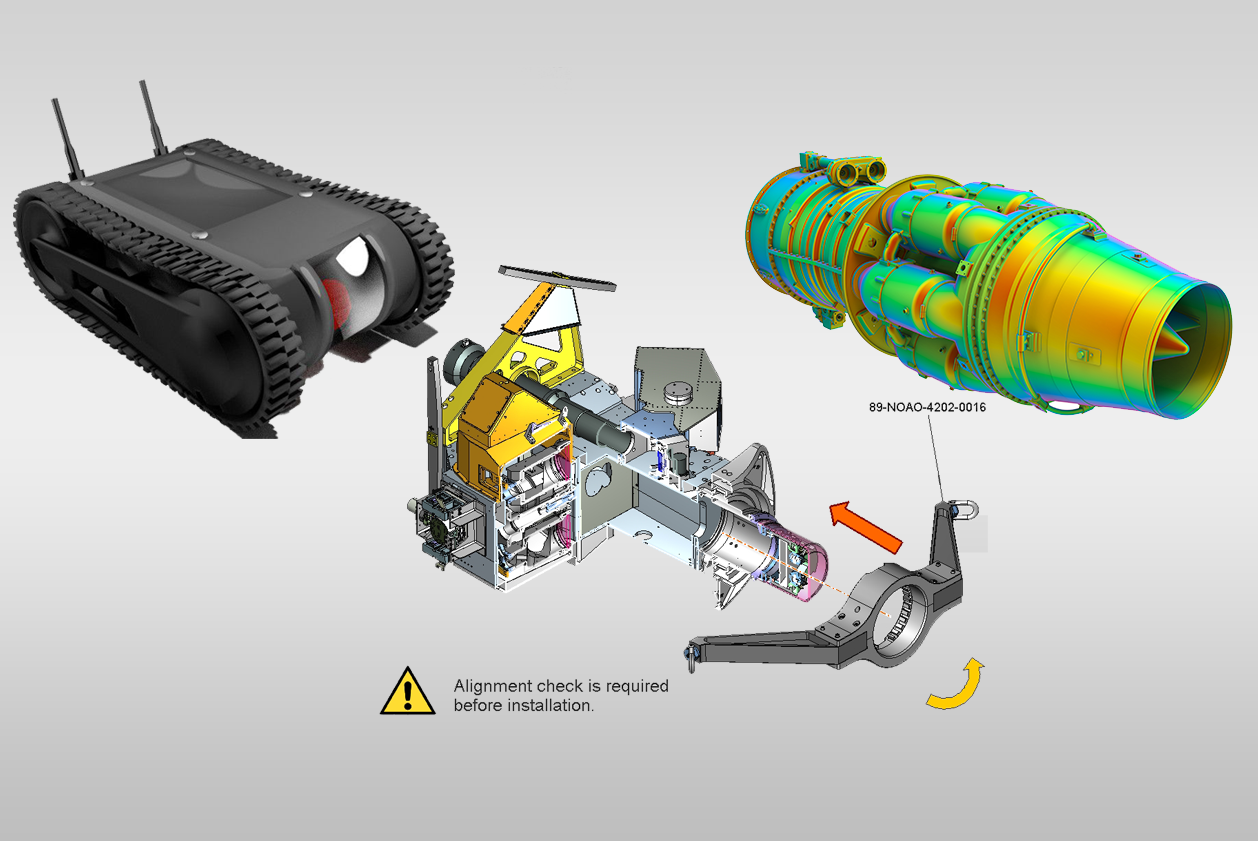

Varsun Aerospace Technologies Pvt. Ltd. is an AS9100D-certified global engineering and manufacturing company, specializing in high-precision machining, design engineering, and quality inspection services.

Founded in 2004, and based in Sultanpur, Telangana, Varsun combines innovation, advanced technology, and strict quality control to deliver components and systems trusted by the aerospace, defense, and high-tech industries.

Mission

"Manufacturing of High Precision and Advanced Technology Products with Quality to match

Global Standards"

Vision

"Varsun envision achieving global leadership in providing sustained value to its clients

by

combining technology skills,

domain expertise, process focus and a commitment to long-term relationship"

Our AS9100D-certified Quality Management System ensures excellence in every component we deliver.

The entire production process is rigorously managed through a three-stage quality control system—IQC (Incoming Quality Control), IPQC (In-Process Quality Control), and FQC (Final Quality Control)—to ensure the highest product quality. Precision instruments, including Croma CMM, are employed to guarantee accurate measurements and precise alignment across all products.